We will keep fighting for all libraries - stand with us!

Internet Archive Audio

- This Just In

- Grateful Dead

- Old Time Radio

- 78 RPMs and Cylinder Recordings

- Audio Books & Poetry

- Computers, Technology and Science

- Music, Arts & Culture

- News & Public Affairs

- Spirituality & Religion

- Radio News Archive

- Flickr Commons

- Occupy Wall Street Flickr

- NASA Images

- Solar System Collection

- Ames Research Center

- All Software

- Old School Emulation

- MS-DOS Games

- Historical Software

- Classic PC Games

- Software Library

- Kodi Archive and Support File

- Vintage Software

- CD-ROM Software

- CD-ROM Software Library

- Software Sites

- Tucows Software Library

- Shareware CD-ROMs

- Software Capsules Compilation

- CD-ROM Images

- ZX Spectrum

- DOOM Level CD

- Smithsonian Libraries

- FEDLINK (US)

- Lincoln Collection

- American Libraries

- Canadian Libraries

- Universal Library

- Project Gutenberg

- Children's Library

- Biodiversity Heritage Library

- Books by Language

- Additional Collections

- Prelinger Archives

- Democracy Now!

- Occupy Wall Street

- TV NSA Clip Library

- Animation & Cartoons

- Arts & Music

- Computers & Technology

- Cultural & Academic Films

- Ephemeral Films

- Sports Videos

- Videogame Videos

- Youth Media

Search the history of over 866 billion web pages on the Internet.

Mobile Apps

- Wayback Machine (iOS)

- Wayback Machine (Android)

Browser Extensions

Archive-it subscription.

- Explore the Collections

- Build Collections

Save Page Now

Capture a web page as it appears now for use as a trusted citation in the future.

Please enter a valid web address

- Donate Donate icon An illustration of a heart shape

Hobbymat MD65 lathe Manual

Bookreader item preview, share or embed this item, flag this item for.

- Graphic Violence

- Explicit Sexual Content

- Hate Speech

- Misinformation/Disinformation

- Marketing/Phishing/Advertising

- Misleading/Inaccurate/Missing Metadata

plus-circle Add Review comment Reviews

2,768 Views

DOWNLOAD OPTIONS

For users with print-disabilities

IN COLLECTIONS

Uploaded by philpem on November 9, 2020

SIMILAR ITEMS (based on metadata)

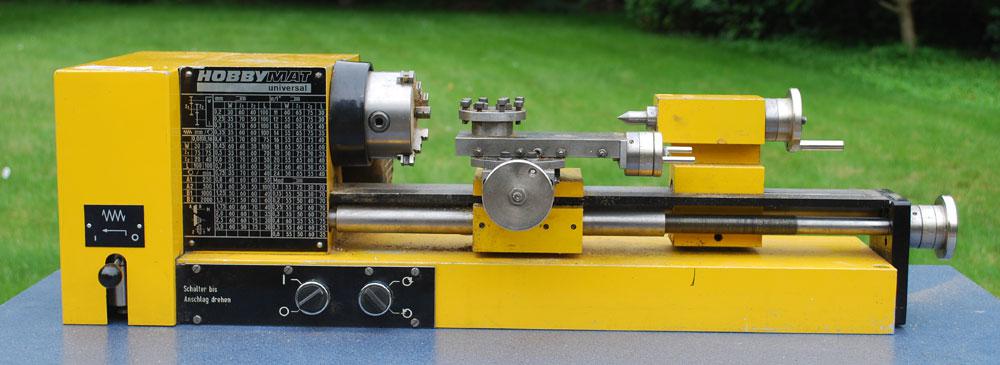

Some photos of My Hobbymat MD65 Lathe

The Hobbymat was made in Eastern Germany until fairly recently and was designed for light duty hobby work. My own was manfactured in 1990, there are some images below which are linked to larger images, but be aware these are ~1Mb each.

My Hobbymat - Click to zoom in

The Specifications are:

This lathe is related to the larger Prazimat lathe but has the considerable advantage of being small enough to be moved around by one person. There are some disadvantages to this, although solidly made from 45kg of steel, clearly this lathe is not in the same league as say an ML7, which is twice the size and weight, but it compares very favorably with many modern small lathes.

The BFE65 milling attachment fits to the bed of the lathe to produce a versatile mill/drill using the cross slide as an XY table. A special milling table that replaces the topslide is provided and can be seen in one of the photographs above. It is alos possibile to buy an XY table for the BFE65 to make a stand alone milling machine.

The Hobbymat MD65 is a precision screwcutting lathe and is supplied with gears for both metric and imperial threads. The electrics are built in and the motor can be reversed. As the chuck is bolted to the spindle, there is no danger of the chuck unwinding itself in reverse as can happen with lathes from Myford and Boxford. The spindle is bored straight through, with a No2 Morse Taper and can pass work of up to 12mm diameter.

All images (c) Mike Willis 2005

machining:md65

- Share via...

- Recent Changes

- Send via e-Mail

Hobbymat MD65 lathe

An old but sturdy east-German (DDR/GDR) metalworking lathe. It was also sold with slight build variations as the following:

- Proxxon MD65

- Proxxon SD300

- Prazi SD300

- SU300 Masterturn

Surprisingly enough it's still on sale –

- Pro Machine Tools -- SU300 Masterturn precision screwcutting lathe

- Eton e.K. supply spare parts

I've scanned the manuals which came with my MD65.

- Some cheeky people have been printing this and selling copies on ebay… save yourself the money and download it here for free!

- This particular MD65 manual isn't branded Hobbymat on the front page. I'm not sure why this is!

- The original manual is about A5 sized, but this scan prints very well at A4 size.

- Essel Engineering slow-speed attachment instructions

- See below for a partial copy of these

- I'm missing the third page which included some additional feed gear settings for coarser pitches.

- Please email [email protected] if you have a copy of the full manual, or type up the missing change-gear settings.

The following document came from the Hobbymat mailing list on Yahoo Groups 'back in the day'. I have it printed off at A4 size and keep it next to my lathe for easy reference.

- Supplementary Notes for the Hobbymat MD65

Lathe tools guide

I don't know where I found this image, but it's another one I have in my quick reference booklet next to the lathe.

Headstock and tailstock tapers

- Headstock: MT2 (Morse Taper)

- Tailstock: MT1 (Morse Taper)

Drive belts

The above drive belts are (at the time of writing) available from:

- Essel Engineering .

- These are toothed on the rear and can be a bit fussy to get on and off the wheels.

- I've also seen other belts appear on eBay from a seller in Poland. These are a more solid design than the Optibelt ones sold by Heritage Lathes, and can be a little easier to get on and off the pulleys.

Tumbler reverse

I've got a partial set of the instructions for this – I'm missing the third page which contains the rest of the list of feeds and speeds. For convenience's sake, I've retyped the instructions here. Capitalisation and punctuation is as per the original document.

I believe this kit was originally sold by Chronos, but they no longer have any copies of the instructions.

This TUMBLER REVERSE GEAR ASSEMBLY has been developed to enhance the capabilities of the HOBBYMAT Type MD65 Precision Lathe and to dispense with the need to, reverse the Motor or, laboriously rewind the Saddle by hand at the end of a turning operation. Because it will now be possible to turn either Left or Right Hand, there will be a considerable saving of time.

Maintenance of the Assembly will be minimal, since the DELRIN GEARS, fitted with OILITE BEARINGS, run on HARDENED STEEL SPINDLES. A GREASE NIPPLE is fitted to facilitate lubrication of the LEADSCREW THRUST BEARING.

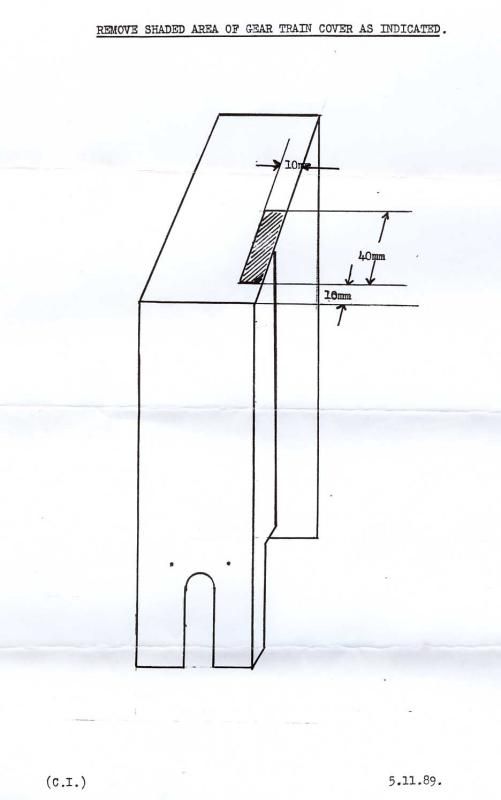

Installation of the ASSEMBLY is quite straightforward and does not require any modification to the basic Lathe, apart from forming a 50 mm X 10 mm slot in the Gear Cover to accommodate the Assembly Operating Lever. Please refer to MD65 Operating Instructions and Spare Parts List for identification of parts listed hereunder.

FITTING INSTRUCTIONS :-

- Remove Gear Train Cover

- Loosen M6 Bolt (Item 24 Page 10) and disengage Clutch from Coupling.

- Remove Coupling and Key together with Circlip (Items 11, 30 and 31 page 38).

- Loosen M8 Bolt and allow the Apron (Items 21 and 1 Page 48) to swing forward.

- Remove Countersunk Screw and Washer (Items 15 and 16) together with Twin Gear Assembly (Items 3, 4 and 5 page 48)

- Remove 100 T Gear and Key (Items 10 and 29 Page 38) from Leadscrew (Item 2 Page 38)

- Remove Apron (Item 1 Page 48).

- Fit Tumbler Reverse Gear Assembly.

- Refit 100 T Gear, Key and Circlip to Leadscrew.

- Refit Twin Gear Assembly complete with 1 X 20 T and 1 X 75 T Gear.

- Refit M4 Countersunk Screw and Washer

- Swing Apron to rear and engage the 75 T Gear with the 30 T Gear on the Headstock Mandrel, allowing the appropriate amount of backlash between the various Gears and tighten the M8 Bolt.

- Refit Coupling and Key.

- Engage Clutch with Actuating Arm and tighten the 6M Bolt.

The Clutch will not operate until the Tumbler Gear is engaged. The THREE POSITIONS are :- Lever TOWARDS the Operator for RIGHT to LEFT traverse, ie. normal operation, Lever AWAY from Operator for LEFT to RIGHT traverse. NEUTRAL is located MIDWAY between FORWARD and REVERSE.

TABLE OF FEEDS :-

(C.I.) 5.11.89.

Editor's note: The original document included a third sheet of paper with additional change gear / feed rate options which is missing. If you have a copy of this (or any other feed gear options you've calculated for the tumbler reverse), please contact me at the email address at the top of the page.

- Last modified: 2023/11/03 02:01

glue-it.com

tools, materials & knowledge for model makers

Hobbymat MD65 Lathe

The Hobbymat MD65 lathe was made by VEB Prazisionsdrehmaschinen in the 1980’s and distinguished by the bright colour paint and the D-section bed.

I′ve owned this lathe from new, bought around 1982.

Specification:

- Centre Height: 65 mm (2.6″)

- Between Centres: 300 mm (12″)

- Turning diameter over carriage: 62mm

- Cross slide travel: 80mm

- Headstock: MT2

- Headstock bore: 12mm

- Tailstock: MT1

- Motor: 250W

- Spindle Speeds: 250, 500, 1000 and 2000rpm

Price: you can pick up a Hobbymat MD65 lathe on ebay for between £300 and £450.

Have had this lathe for more than 25 years and it still does as good a job now as ever. For a 25 year old lathe it cleans up rather well and with careful care, adjustment and oil the results are still as good as when it was new.

Note that there is no motor cut-out and so you can start the lathe by accident with your fingers around the belts and so make a habit of disconnecting the lathe from the mains before lifting the cover.

The 250W motor has ample toque for all of the spindle speeds that this machine has: 250, 500, 1000 and 2000rpm. Now and again it would be nice to be able to go down to 100rpm, but this machine is in it’s element at 1000rpm and 2000rpm.

The gears for thread cutting can be seen in the tray on the right, these are glass reinforced nylon gears and based on the fact that these are over 25 years old they are in quite good condition.

They do however collect a lot of dirt and debris over time and so it is best to brush them out and hoover them clean every so often. I run the gears dry and normally just have a set installed for fine powered traverse of the saddle.

The intermediate gear reduction then drives in this case a larger black coloured gear that is fixed to the end of the leadscrew via a dog clutch. The handle for the dog clutch can just be seen disappearing out of the bottom of the image.

I have used this lathe over the years for model making and so it has to deal with metal, wood, gear cutting, thread cutting and a number of plastics. I will post pages on these subjects and the use of this lathe.

I′ve used this Hobbymat MD65 lathe for over 25 years and it still as strong as when I first bought it. The on-off switch gave up some years ago and I replaced it with a switch from Maplins, otherwise it is perfect.

I actually think this is a better lathe than one of the Mini Lathes in various colours from China. You can buy a secondhand HobbyMat for under £500 as of 2012.

Further Reading:

- Gear cutting – a combination of the MD65 and Unimat 3

- Thread cutting with the MD65 – plus a modification with a handle to allow threads to be cut up to a shoulder.

Machining and Polishing a Perspex Light Bulb – with the hobbymat running at 1000rpm I use lots of cutting oil and ever increasing abrasive grit numbers to gradually smooth and then polish the perspex.

37 thoughts on “Hobbymat MD65 Lathe”

Does anyone know what center I need for de tailstock of the MD 65. And are there some tips for the mounting of the chise. The position of the chisel holder is not in the middle of the center. Thanks in advance

I’m sure the tailstock is MT1

Chisel? Do you mean lathe tool and how this is mounted in the toolpost? I use 6mm or 1/4″ tool bits and adjust the tool to height using metal shims (old feeler gauges work well as shims).

My Hobbymat was out of true on long bars and it was because the weight of the motor hanging off one side twists the bed. I fitted an adjustable foot under the motor and that sorted the problem.

didn’t think of that, could you send a picture?

Not easily – the lathe is in between corner and fridge freezer. I turned the lathe upside down and drilled and tapped M8 into the the bottom of the yellow casting 1″ from the back of the lathe, at the centre of the motor’s mass. I then took some 2″ diameter brass to spread the load on the (presumed soft) kitchen top, drilled and tapped it axially M8, and screwed in a piece of M8 studding with Araldite to lock it. Once cured, M8 nut and washer were added, and studding screwed into lathe. Foot height was adjusted until lathe machined true, then locked off with M8 nut onto washer onto yellow casting.

The whole thing could have been done more simply by putting a toolmaker’s cone underneath the casting.

your description is great and works, thank you, Nigel

Ik heb de kogellagers vervangen met conische rollagers maar ik heb problemen met de Franse documentatie van deze MD65 draaibank om deze draaibank weer compleet te kunnen monteren door die Franse taal hoe kan ik dit oplossen is dit ergens te koop in het Nederlands of Engels

Hello Ronny, there is a manual online that is in english: https://www.philpem.me.uk/_media/machining/md65/hobbymat_md65_manual.pdf

Hope that helps, Nigel

wow i would like to thank you very much i have printed everything now and i will bring it to my workshop and now i can gradually finish the MD65 thank you again really

you are very welcome

Hi, I have a Hobbymat MD65 which has been fine but hasn’t been used for a couple of years. When I tried to use it the other day, I couldn’t turn the lead screw by hand, though it works fine on the power feed. Any ideas?

Hi John, If the leadscrew moves with the power feed and not by hand it sounds like the dog clutch is not fully disengaging. Or it is over tight: 1. might be something stuck in the guard – I normally use lots of engine oil on the leadscrew 2. the handwheel might have been overtightened, loosen the lock nut and rotate it back a bit. You might get too much slack at first, but you can at least check it’s not that. 3. nut in the carriage might be too tight, cannot remember if there is an adjustment – will have to have a look. Best regards, Nigel

Thanks Nigel, I think that you are right, the dog clutch won’t disengage, in fact it seems to be jammed solid now and the engage/disengage handle won’t move at all. It also looks like the lead screw has shifted to the right – there is a gap of about 5 mm between the locking ring and the hand wheel at the right hand end. Any thoughts? John

Hi John, the handle lifts to disengage, but must admit that the handle on my Hobbymat appears to be locked too. I will have to take it apart and have a look. There is a bolt underneath that locks the handle onto the pin that is cantilevered from the main lathe base casting. Best regards, Nigel

Hi On my headstock. It doesn’t look as if there is a MT2 on it. Is this possible? Thanks Jannie

Hi Jannie, There appear to be a few variations on the lathe design and so not surprised. You could just use a straight shank taper in a chuck if you want to turn between centres. Best regards, Nigel

Hallo iedereen, ik heb deze draaibank gekregen van mijn vader (de versie voor houtdraaien, MD 120).

Hoe wordt de kop aan de aandrijfzijde vervangen? Er is een ondiepe uitsparing in de kop. Moet dit met een haaksleutel? Dergelijke sleutel komt niet voor in het instructieboekje.

Zoals de zaken er nu voorstaan kan er enkel tussen de centers gedraaid worden.

Opa Pettson

Hello Opa, sorry, not familiar with the wood turning version. The metal working lathe uses studs and nuts to bolt the chuck onto the spindle. Might be worth asking on the UKworkshop forum: https://www.ukworkshop.co.uk/threads/hobbymat-wooden-lathe.88901/

Best regards, Nigel

Hi Nigel, My late dad gave me a Hobbymat MD65 which I look forward to working with. I haven’t used a lathe in some time but here goes. My issue at the moment is I am unable to swap the Tailstock Chuck with a Centre Spindle. All I have achieved so far is to remove the Chuck Head from it’s tapered shaft which is still stuck on the shaft that moves in & out of the Tailstock. Any help will be appreciated.

Hi Dave, The Hobbymat is a really good lathe. I imagine the taper has had some oil or moisture on it and has rusted in place. If you wind the tailstock fully back the taper gets pushed out. It might be necessary to use some penetrating oil left for some time and then try winding it back again. I must admit that I haven’t taken the tailstock apart to see exactly what’s what, but will have a look. I also have a manual somewhere. Best regards, Nigel

Hello, I have the exact lathe but have not been able to locate a manual anywhere.. what are the chances of getting a scan if you find yours? Sean

Hello Sean, I will have a look through the pile of manuals and see if I still have it. Best regards, Nigel

Where canning her a cope on the instructions to use this please as if been given one ans want the book to read up on it

Hello, it appears that there is a manual for the MD65 available on lathes.co.uk the other way is to contact the company that makes the new version of this lathe (SU300 Masterturn) and see if they could send you a copy. Best regards, Nigel

hello my dear, thank you for your sharing about information of hobby mat md65 machine.i need your help more than this . i want to made some gears of my machine but i dont have free body map of that . of course you had put some information in your site but that is not enough to made it . that is nice of you that send me its information.i mean change gear . for example 60 , 40 , 100t gears.

Hello Ramin, if I understand correctly you would like the dimensions of the change gears that drive the leadscrew? Best regards, Nigel

Ive had an MD65 for about 25 years now and love it, never let me down. It’s going to my new workshop soon and I’m wondering how people mount there’s? Bolted to a bench, free standing or on its own stand and if so, what make?

Hi Paul, my MD65 is bolted to a piece of old kitchen worktop. It’s slightly out though when machining long parallel bars and I think this is down to the worktop slightly twisting the base…best regards, Nigel

Bonjour Pourriez vous me donner le prix du tour HOBBYMAT MD 65 et le prix d’un plateau a mors pour le MD 150 merci

Hi, sorry, not for sale here, there are often MD65’s available on ebay or there is a new version of this lathe known as the SU300 EmcoMachineTools.co.uk Hope this helps, best regards, Nigel

Hi Nigel, Thanks for sharing your knowledge, it’s really helpful I would love to add a variable speed motor to my Hobbymat but where to find a suitable motor to fit in place of the original, would you have any tips on this? Thanks

Hi, you could just use a single phase speed controller? Or you could mount a motor on the bench the other way round – ie the pulley is in the same location as the current motor, but the motor itself is pointing at the original motor. That way you could fit a bit larger 3 phase motor and a single to 3 phase controller – most inverters will run in both directions and so the fact the motor is the wrong way round won’t matter. You will have to construct a housing, but you could use MDF for this and just varnish it. Best regards, Nigel

Ik geloof dat ze zijn verzegeld voor het leven lagers

dank u,ik denk! as demonteren, wassen in petrol,drogen, insmeren met lager vet, en terug monteren zonder spel,zal de oplossing zijn. Beste groeten.

Beste, nergens vindt ik het smeren van de hoofd as, hoe dat moet?of die met olie draait of smeervet? weet u daar het antwoord op?

@znidarsic eduard

Ik heb de lagers van de spil van een MD65 ingevet met kogellagervet op lithium basis (bv. Facom groen vet). Een heel verschil qua geluid, ze stonden zo goed als droog. Wel even wat werk om alles te demonteren en de spil kwam er niet so makkelijk uit.

“I greased the spindle bearings of an MD65 with lithium-based ball bearing grease (eg Facom green grease). A lot of difference in sound, they were almost dry. Some work to disassemble everything and the spindle did not come out that easy.”, Thanks David, must admit that I’ve never checked the bearings, always assumed they are sealed for life, Best regards, Nigel

Leave a comment Cancel reply

- Search forums

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Lathes and other Machining Equipment

Hobbymat MD65 Help please.

- Thread starter soft top

- Start date Jan 15, 2017

- Jan 15, 2017

Hi, I have not touched a lathe since I learnt basic turning during my engineering apprenticeship 40 odd years ago. I have now been asked to help/teach our 16yr old foster kid how to use one. Problem is that the lathe we have been given has no tool post, most of the gear set and centres missing. For now I can make it usable if it had a tool post. I have been looking at them on ebay but we are unsure which of them would fit the hobbymat. They all seem to have a central fixing bolt but it looks like the original had a two bolt fixing. Can we use just one of the holes to fit a tool post? Also unsure what size tools should be used with this lathe. Would appreciate it if someone could give me a link to a basic one on e bay that we could use? Or better still, anyone got one for sale?

Forum Supporter

Couple of pictures and the lathe model numbers would help too

Eye id have known that had i looked closley instuction book for it on the bay of evil 6 quid

- Jan 16, 2017

take it from me optima has done some loverly work on the lathe you have there and has some posts on here on updates for the machine as well

Yup, and the gear sets are two bob for those so no reason why you can't find replacements.

you may need something like this http://www.ebay.co.uk/itm/Mini-Quic...068478?hash=item41ae5aebfe:g:x7wAAOSwiDFYKrQ2 or like this http://www.ebay.co.uk/itm/Quality-L...402885?hash=item4645103d45:g:LTsAAOSwl-FXNXHv optima will advise better

If you want to use it now you don't "need" a tool post, you can use this method , as employed on older larger lathes. One stud in the threaded hole in your compound slide will be more than sufficient on a little lathe. Get some packing that gets the tool on centre height and keep it with the tool.

rory1 said: If you want to use it now you don't "need" a tool post, you can use this method , as employed on older larger lathes. One stud in the threaded hole in your compound slide will be more than sufficient on a little lathe. Get some packing that gets the tool on centre height and keep it with the tool. Click to expand...

optima21 said: the problem with the hobbymat is that if you want to use a "normal" quick release tool post you you can't use the topslide, so you need to machine a base that bolts to the cross slide. here are a couple that I made earlier. the one on the left I was using for about 15 years and the one on the right I made a couple of years ago. you can see the holes in the bases where they screw to the cross slide. Click to expand...

- Jan 17, 2017

Thanks for the replies. They have helped a lot. I now realise that I cant fit any of the tool holders that are on e bay as they will be too high.We would like to keep the original top slide on the machine so today I made a clamp to hold the tool. If, later I can find an original tool post then I will fit that. I have also ordered some 8mm tool bits and I found a free download of the manual. Optima21.......Was wondering if you still have your old Hobbymat tool post? If so, would it be for sale???

That origional clamp would make a good first project. Fixing hole centers can be measured. Thickness easy to guess. 10 mm would work. Pcd and diameter could be easily worked out with a pair of dividers from a center hole between the fixing holes.

sorry the parts for my lathe arn't for sale, I've had it since new in 1991, and it is complete with all original parts. If you have access to a pillar drill, you could make one using a peice of 60mm diameter steel bar 25mm long, and that could be an easy project to do http://www.ebay.co.uk/itm/291774055803

addjunkie said: That origional clamp would make a good first project. Fixing hole centers can be measured. Thickness easy to guess. 10 mm would work. Pcd and diameter could be easily worked out with a pair of dividers from a center hole between the fixing holes. Click to expand...

Yes, but measuring and guestimating is a very important part of the learning process

- Jan 18, 2017

optima21 said: sorry the parts for my lathe arn't for sale, I've had it since new in 1991, and it is complete with all original parts. Click to expand...

- Jan 19, 2017

- Multirotors

- Classifieds

- Remember Me Forgot Password?

- External Feeds USENET (aka Newsgroups) uk.rec.models.engineering Cleaning up a Hobbymat MD65 lathe

- Electric Flight

- Advertising

- Our Sponsors

- Review Policies

- Terms of Service

- Privacy Policy

- Site History

- Mark Forums Read

- Member Search

- Upcoming Articles

- Do Not Sell My Data

- Manage Consent

- Back to Top

Je fait ce site afin de parler de technique de mécanique et d'ajustage

dimanche 7 octobre 2012

Filetage avec un tour hobbymat md 65.

5 commentaires:

Bonjour, je viens d'en acheter un hobbymat md65 mais je n'ai pas tous les pignons pour filetage. Je voudrais au moins le jeu des pignons à mettre pour le filetage pas métrique de 1,5. Je viens vers vous pour m'aider. J'ai un ami qui peux me fabriquer les pignons. J'aurais besoin d'un scannage de vos pignons ou photocopie, afin de les avoir grandeur nature Ou mesurer le diametre exterieur et nombre de dents ou une autre methode. Mon mail est [email protected] et mon n° tel : 0602711524.Merci d'avance pour votre réponse.

Bonjour vous pouvez trouver des pignons au module chez C.I.R. ils les fournissent en acier ou en matière composite Vous avez sur le Blog le manuel du tour, ou il y a le nombre de dents pour les pignons (filetage 1.5) et vous copiez l’épaisseur le diamètre intérieur et le clavetage des pignon qui sont montés sur votre tour Cordialement

Bonjour Pouvez vous me donner l adresse du site cir? Je suis tres interresé mais je ne trouve pas.. Merci

Voici le lien de CIR http://www.cir.fr/

Bonsoir L'inter centrifuge du moteur de mon MD65 s'est brisé. Savez vous ou trouver ce genre de pièce ou faut il changer le moteur et le remplacer par quoi? Remerciements

Sign in / Register

Sold March 2011 Back to Archive

Hobbymat md65 lathe - stock code 4327.

4327 - Hobbymat MD65 lathe

- Description

Station Road Steam Limited

Registered office address: Unit 16-17 Moorlands Trading Estate , Metheringham, Lincoln, Lincolnshire, LN4 3HX.

Company registration number: 4496691

VAT Number: GB803743934

Copyright © Station Road Steam Ltd 2001-2024

- Meet the team

- Workshop facilities

- Just arrived

- Model Engineering Clubs

- Terms of business

- Privacy policy

- Email: [email protected]

- Tel: 01526 328772

Machines outils, Usinages et Documentations

Tour Hobbymat

Passion-Usinages --> :: Machines Outils Conventionnelles :: Tours

Re: Tour Hobbymat

Passion-Usinages :: Machines Outils Conventionnelles :: Tours

- Créer un forum | © phpBB | Forum gratuit d'entraide | Contact | Signaler un abus | Forum gratuit

- Messages non lus

- Messages récents

- MACHINES OUTILS CONVENTIONNELLES

Changement moteur sur tour HobbyMat MD65

- Auteur de la discussion osegouin

- Date de début 22 Mar 2008

- 22 Mar 2008

Bonjour, Ayant récupéré un tour Hobbymat MD65 mais avec un moteur HS, que me conseillez vous comme moteur de remplacement j'ai aussi récupéré un variateur de 0,5Kw micromaster ou puis je trouver un moteur compatible avec tout cela ? merci d'avance Olivier

- 23 Mar 2008

Salut osegouin et bienvenue sur le forum Quelle est la puissance du moteur d'origine ? Ton vario est un vario qui sort du tri du monophasé ou du courant continu ? Pour l'achat du moteur internet reste la solution de la simplicité pas besoin de te déplacer mais je suis sur qu'il y a dans ton coin un vendeur ou réparateur de moteurs électriques

Bonjour, Puissance d'origine 435 W, mon variateur est un variateur Mono en entrée, qui sort les 3 phases TRI , U,V et W en sortie Si vous avez des liens Ebay ou autre je suis preneur, ou si vous avez des offres ?

En allemand cela donne quoi moteur triphasé ?

bjr, Recupéré sur le forum cyberbricoleur Sur les specs du tour hobbymat MD65 (maintenant SD300) Vitesses de la broche : 250/500/1000/2000 tr/mn Puissance : 250 W Moteur 110V/60Hz - 230V/50Hz Aucune indication de vitesse du moteur (en principe 1500 ou 3000 T/mn) a voir sur la plaque du moteur Un moteur de 1500 T/mn a la place d'un 3000 T/mn baisseras la vitesse de broche mini ( c'est mieux pour le filetage ) Il faut voir aussi le systeme de fixation du moteur sur le tour ainsi que l'espace disponible A+ pierre

ben ça donne ça : http://cgi.ebay.fr/ws/eBayISAPI.dll?Vie ... :IT&ih=016 Et voilo !

osegouin a dit: Bonjour, Ayant récupéré un tour Hobbymat MD65 mais avec un moteur HS, que me conseillez vous comme moteur de remplacement j'ai aussi récupéré un variateur de 0,5Kw micromaster ou puis je trouver un moteur compatible avec tout cela ? merci d'avance Olivier Cliquez pour agrandir...

j'ai un tour hobbymat md65 depuis 20 ans le moteur à lâché je l'ai donc remplacé par un Moteur BONANI "type 1 S63B2" qui après quelque adaptation au montage fonctionne très bien si vous êtes intéressé ??? garrett

Voici sur mon blog le moteur que je viens de monter sur mon tour Hobbymat md 65 qui à 20 ans et qui est reparti pour continuer sa longue carrière http://techniqueetmecanique.blogspot.com/ Garrett

Sujets similaires

- 14 Mar 2024

- 10 Jan 2024

- Electricité, variateurs, convertisseurs et moteurs

- 21 Fev 2022

- Combinés tour-fraiseuse

- 10 Avr 2024

- 18 Fev 2024

- 11 Mar 2024

- 22 Nov 2023

- 23 Mai 2023

- 23 Mai 2021

- 4 Août 2022

COMMENTS

Instruction manual for the Hobbymat MD65 lathe. Scanned from my original A5 printed copy, cleaned up. Prints very nicely at A4 size. Addeddate 2020-11-09 13:17:30 Identifier hobbymat-md-65-manual-scanned-pap Identifier-ark ark:/13960/t3nw93f7b Ocr ABBYY FineReader 11.0 (Extended OCR) ...

HOBBYMAT MD65 Manuel | PDF. .'. Tour parallele ·de precision type MD 65 Notice technique et liste des pieces de rechange ... (' .. - Nous vous prions de lire attentivement la presente notice accompagnant votre tour parallele de precision et de tenir scrupuleusement compte des indlcations qu'elle contient.

Tour Hobbymat. Voici des photos du montage d'un moteur sur un tour Hobbymat MD 65, en remplacement de celui d'origine. Le tour Hobbymat MD 65. La plaque du moteur de remplacement. Le moteur dont une plaque de remplacement à été fabriqué pour cacher les fils. L'axe du moteur faisant 11mm un manchon est fabriqué à partir de l'ancien axe.

Fabrication avec un tour Hobbymat d'un filetage de support d'appareil photo ou de longue vue !

The Hobbymat MD65 is a precision screwcutting lathe and is supplied with gears for both metric and imperial threads. The electrics are built in and the motor can be reversed. As the chuck is bolted to the spindle, there is no danger of the chuck unwinding itself in reverse as can happen with lathes from Myford and Boxford.

First cuts on my Hobbymat MD65, never used a lathe before buts its nice to know that some of the techniques follow through from a milling machine! Decided to...

Change Gears for Hobbymat MD65. A box of spare gears used to create the other spindle to leadscrew relationships - ie to allow you to create the other thread pitches. You can see a metal spigot in the centre of one of the gears with a key to locate it. Machining a thread up to a shoulder on the lathe takes some time and experience to master.

Please refer to MD65 Operating Instructions and Spare Parts List for identification of parts listed hereunder. FITTING INSTRUCTIONS :-. Remove Gear Train Cover. Loosen M6 Bolt (Item 24 Page 10) and disengage Clutch from Coupling. Remove Coupling and Key together with Circlip (Items 11, 30 and 31 page 38).

The Hobbymat MD65 lathe was made by VEB Prazisionsdrehmaschinen in the 1980's and distinguished by the bright colour paint and the D-section bed. ... Pourriez vous me donner le prix du tour HOBBYMAT MD 65 et le prix d'un plateau a mors pour le MD 150 merci. Reply. Nigel. May 20, 2020 at 8:52 pm ...

tour a metaux hobbymat md65 (allemand) Message par E-go » mer. 14 nov. 2012, 12:49 salut tout le monde . je change mon tour , donc je vend celui avec le quel j ai tourné tout mes mods , jusqu a aujourd'hui . il est bien sur parfaitement fonctionel ne comporte pas de jeux qui ne soient réglable avec les lardons . le moteur tourne impeccable ...

the 8 holes for clamping the tools down with are M5 and 50mm diameter. also don't overtight the bolt/cap head bolt that you use to mount things to the topslide, or you can break the topslide. the original M8 bolts are turned down below the head to about 4mm to 5mm so the bolts will snap rather than topslide. 1. 2.

Re: Cleaning up a Hobbymat MD65 lathe. On Mon, 08 Aug 2011 19:26:06 +0200, Erik Olsen wrote: > The holes are on the circumference, and the C spanner type shown (with a. > pin nose) is the correct tool to use. Specifically, a 30 to 32mm C-spanner ("hook spanner") with a 4mm pin.

Hobbymat MD65 - care and maintenance. By Lissadell, October 15, 2023 in Model Engineering Forum. Share More sharing options... Followers 0. Recommended Posts. Lissadell. Posted October 15, 2023. Lissadell. Members; 125 Share; Posted October 15, 2023 (edited) Sorted now - have ordered some Slideway oil and was advised iso32 would be fine rather ...

Bonjour, je viens d'en acheter un hobbymat md65 mais je n'ai pas tous les pignons pour filetage. Je voudrais au moins le jeu des pignons à mettre pour le filetage pas métrique de 1,5. Je viens vers vous pour m'aider. J'ai un ami qui peux me fabriquer les pignons.

A Hobbymat MD65 lathe - we had a new one of these in a while back, I was impressed at the quality of engineering in what is quite a small bench lathe. This one isn't new by any means - you could even go so far as to say it looks a bit scruffy - however, there are no horrendous lumps carved out of the bed, all the knobs go round as designed and ...

Bonjour, Je viens de faire l'acquisition d'un tour HobbyMat MD65 mais ne dispose pas de la notice en Français. Étant néophyte en la matière, celle ci m'est absolument indispensable tant pour connaître la machine que son utilisation. Un grand Merci à la personne qui aura la gentillesse de me répondre. gladus63.

Tour Hobbymat. J'ai besoin de votre avis svp. J'ai l'opportunité d'acheter un tour hobbymat MD65 neuf jamais servi (cause décès) pour 450€. Je joins quelques photos. Merci de me dire si c'est une affaire.

Compagnon. Il ne faut pas oublier que le changement de vitesse par courroies permet d'augmenter le couple pour les vitesses basses. Même si une conversion tri/vario est une solution intéressante, elle n'exclue pas totalement le changement de vitesse sur les poulies surtout que le moteur du MD65 n'est pas très puissant.

Apr 21, 2020 - Voilà je viens d'acquérir un tour Hobbymat MD65 après avoir consulter les différents avis sur le forum. :-D J'en suis content mais les commandes été un peu...

Sur les specs du tour hobbymat MD65 (maintenant SD300) Vitesses de la broche : 250/500/1000/2000 tr/mn. Puissance : 250 W. Moteur 110V/60Hz - 230V/50Hz. Aucune indication de vitesse du moteur (en principe 1500 ou 3000 T/mn) a voir sur la plaque du moteur. Un moteur de 1500 T/mn a la place d'un 3000 T/mn baisseras la.